Surplus electricity from wind power

| 20-10-2020 20:44 | |

| Into the Night (21582) |

GasGuzzler wrote: There is no efficiency at idle. Nothing is being translated to forward motion. Gasoline has the highest BTU available by volume. Kerosene and diesel oil have the highest available BTU by weight. Both engines will use approximately the same BTU at idle. Both engines have a power curve. It is this power curve that helps determine the efficiency of that engine design under load (such as driving down a highway, lifting a bucket of dirt on a loader, etc). Efficiency is also determined by the transmission system, the method of driving the machine forward (tires or steel wheels or propeller) which is called the coupling efficiency (which can also be affected by ice, snow, rain, temperature, humidity, etc). Total machine efficiency is calculated from these factors. There is no magick fuel. There is no magick engine design. There is no magick transmission or coupling system. The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 20-10-2020 21:38 | |

| Into the Night (21582) |

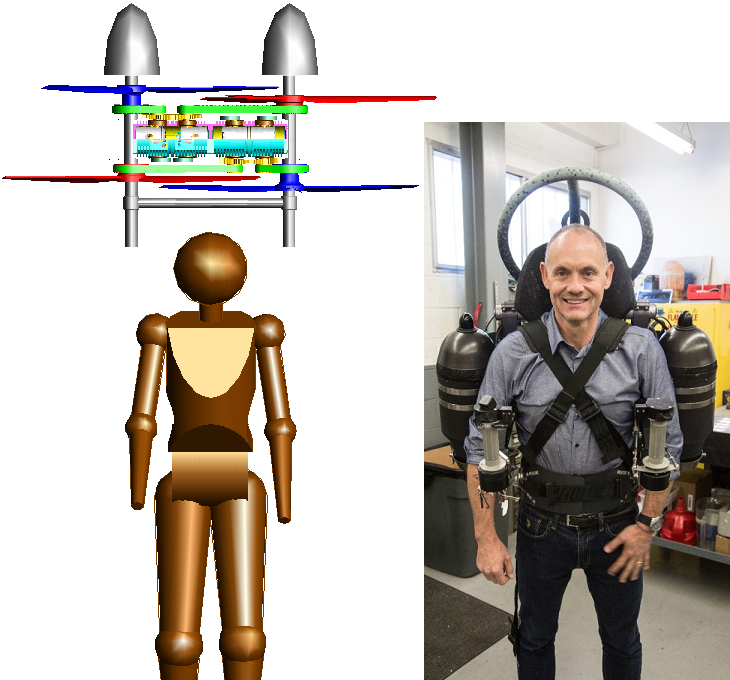

Xadoman wrote: These types of engines have been around a long time. Their main problem is one of cost to build. The most expensive component in any engine is the crankshaft. Pulse power gears are not cheap either. This engine uses two crankshafts and they must be geared together with pulse power gearing (heavy duty gears that can take the pulsating power. Transmission gears are coupled through a flywheel and a slip mechanism of some kind (either mechanical or hydraulic). This heavily reduces the pulsating load on the teeth of the gearing, allowing for a simpler hardening method (usually surface nitride treatment). Pulsed power gearing, on the other hand, require specially treated metals, making them more expensive. The cylinder head, along with it's valve train (camshaft, rockers, and camshaft coupling (either gears or belt) is not as expensive as portrayed in this ad. A further problem is waste heat. Yes, despite the efficiency there is still waste heat. This must be discarded or the engine will exceed it's material tolerances. Combustion in this engine takes place at the center (where the two pistons come together) and thermal is more difficult to efficiently move from that area. Cylinder heads are more than just part of a valve train. They are also a mass that helps to remove excess thermal energy to the surrounding air. Aircraft engines don't have a cylinder head. Instead, entire cylinders are bolted onto a crankcase. These cylinders are built as a unit, contain the pressure chamber (the part the piston moves in), the valves, the rockers, and associated plumbing. This places the seal between the crankcase and the cylinder at a lower pressure area (just crankcase blowby pressure) rather than at the joint of high pressure near the valve heads as is done in car engines. The advantage of a head gasket (now that we have better gasket materials!) is that all the control systems of a cylinder can be dealt with as a unit, instead of on individual cylinders as is done on reciprocating aircraft engines. Yes, the engine is efficient, but it does have it's drawbacks. It is also still a reciprocating engine, with it's attendant advantages and disadvantages. Engines like this have already been used in equipment, ships, tanks, and elsewhere through the years from time to time. One of the most efficient engines ever built is the modern tubojet engine while operating at altitude (they positively suck while taxiing around on the ground!). Turboshaft engines are pretty damn good too, but their coupling is less efficient. Xadoman wrote: An interesting idea. No practical machine has been designed yet as far as I can see. He only shows the engine itself and it's coupling system (the four propellers and gearing), the backpost and body support system, and of course ideas on how to control it. He seems to consider the use of air resistance in the downwash to guide the machine. I see several problems with this design, though there might be potential here: No fuel tank. This thing is going to require fuel. A lot of fuel. The pilot is going to have to wear the fuel tank. Further, wearing such a thing is not only heavy, but interferes with the air resistance method of controlling the machine. It seems naturally unbalanced, since the machine is supported by a back post. I assume a practical machine will do more to center the line of thrust). The machine won't glide. It won't autorotate either. Failure of the powerplant as designed means certain death since the gearing prevents it. Autorotation can possibly be implemented through the use of one way clutches on the propeller shafts, but the problem here is lack of control. This is also a gutsy maneuver, and it's not for the faint of heart to perform it. It takes training to overcome this and to filter out those not capable of performing it. It is part of helicopter training (useful for autogyros as well, though they glide). This machine is essentially a moving wing ultralight, and might be able to operate under part 103 or as an experimental aircraft under part 91. Under current rules, such machines do require signoff from an an instructor, but no license if under part 103. A recreational pilot's license is sufficient for part 91 flight, as long as the flight is daytime only and VFR, which I assume would be typical use of this machine. The idea of keeping hands and legs free while flying is attractive. Too many designs of this type limit these freedoms, sometimes even encasing hands in special holders. Kinda makes it tough to take that selfie. Aerobatic maneuvering seems very limited. If the machine gets itself into an unusual attitude, recover may not be possible, resulting in the machine powering itself into the ground (and you with it, probably headfirst). Messy. There are some good ideas here, but it will take much more to turn it into a practical machine. The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan Edited on 20-10-2020 21:47 |

| 21-10-2020 04:34 | |

| GasGuzzler★★★★★ (2932) |

Into the Night wrote:GasGuzzler wrote: Does it need to be forward motion? Even at idle, it has to produce the DC power to run accessories-fans, radios, lighting, chargers, ect... It peaked my interest when Xperson mentioned low load efficiency, I've often marveled that a big diesel can run all night on so little fuel, still powering up all the goodies. Is there no efficiency comparison for doing this work? I suppose then you'd also have to compare with the same alternators and what not... Radiation will not penetrate a perfect insulator, thus as I said space is not a perfect insulator.- Swan |

| 21-10-2020 05:24 | |

| Into the Night (21582) |

GasGuzzler wrote:Into the Night wrote:GasGuzzler wrote: That is the best direction for the transmission in terms of efficiency. GasGuzzler wrote: Only if you use 'em. A gasoline engine also has to power the spark plugs. That's not a choice with the things. GasGuzzler wrote: No spark plugs in a diesel engine. For this purpose, the diesel wins. GasGuzzler wrote: I don't think anyone has ever really calculated it, since it's not really an easy comparison with different alternators, different kinds of loads (like I say, gasoline engines have to power their own spark plugs). The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 21-10-2020 06:10 | |

| GasGuzzler★★★★★ (2932) |

Into the Night wrote:GasGuzzler wrote:Into the Night wrote:GasGuzzler wrote: I never even considered the spark plugs. Yup, I've been hit once or twice. It would take a bit of energy to power those things. They pack quite a punch! Makes sense. Radiation will not penetrate a perfect insulator, thus as I said space is not a perfect insulator.- Swan Edited on 21-10-2020 06:11 |

| 21-10-2020 07:01 | |

| manolis☆☆☆☆☆ (10) |

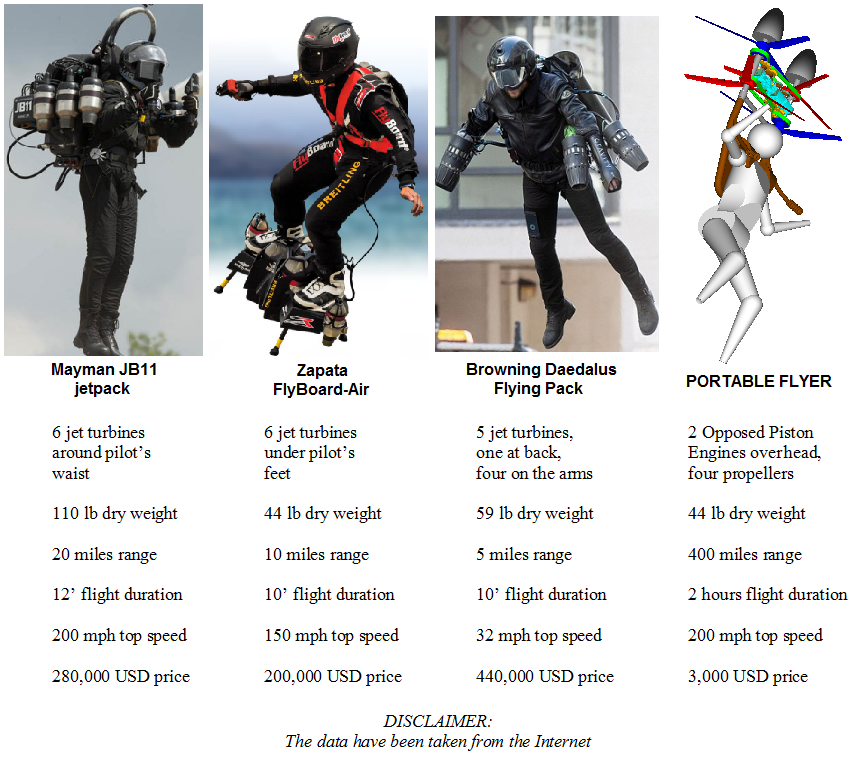

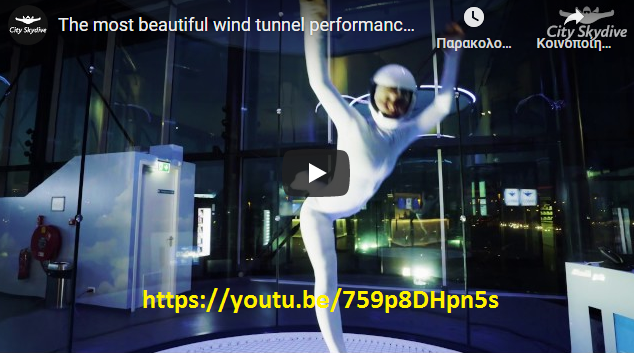

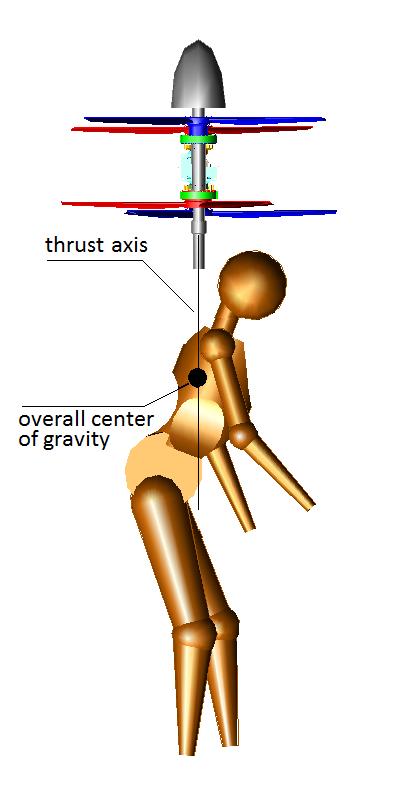

Hello all. IntoTheNight, sorry but I have to disagree with several things you write. Here are some of them: The crankshaft is not the most expensive part of a typical four-stroke engine. The cylinder head is. An Opposed Piston engine needs not two crankshafts (see the PatOP Diesel engine at https://www.pattakon.com/pattakonPatOP.htm )  The heat loss through the cylinder head is not an advantage. If you eliminate the cylinder head, the thermal loss decreases (because the combustion walls area decreases) and the thermal efficiency improves. The synchronization gearwheels are not necessarily heavily loaded (if the load is symmetrical, say one electric generator per crankshaft, or, say, a propeller per crankshaft) and the crankshafts run at zero phase difference, the synchronization gearwheels run unloaded. In the following Portable Flyer the synchronizing gearing runs without lubrication because it runs unloaded:  The OPRE and PatOP designs are different than the known Opposed Piston engines. Their connecting rods are heavily loaded only in tension. With their "pulling rod architecture" the combustion happens in the "slow dead center" providing substantially longer time (say, 35% more time) to the fuel to get burnt efficiently (at high "expansion ratios)". Their pulling-rod-architecture transfers the thrust loads away from the hot exhaust ports of the cylinder, providing "like 4-stroke lubrication". The "small" turbines (say, those providing less than 500PS) are anything but efficient. Their "actual" overall efficiency in the JetPacks (Yves Rossy, Zapata, Mayman, Browning) is around 2%. See the following table:  They consume a full tank in less than 10 minutes. The control of the Portable Flyer is based on the "Weight displacement" (as the JetPacks) and on "Aerodynamic" (the pilot can deflect a part of the downwash of the propellers to yaw, or pitch, or roll). It is not easy to get. When a problem is difficult, the reductionism is the way to go: 1. The astronaut. The case with the astronaut who "flies" in empty space (out of the air), outside or inside a gravitational field, shows that the "Weight Displacement Control" provides full control. The propulsion unit provides a pure thrust force and is secured to astronaut's body. The pilot displaces the overall center of gravity relative to the thrust force axis by varying their body posture. The offset thrust force – relative to the center of gravity – turns the assembly and redirects / re-vectors the thrust force.  The astronaut can turn at any desirable direction and can go from any point A to any point B avoiding any obstacles between these points, following any path they like. The astronaut can also take off and land. Without air to interact, the astronaut has no aerodynamic control, at all. The thrust axis is what matters, not the exact point where the propulsion unit is located; for instance, if the "thrust provider" has zero weight, then either the thrust provider is above the head of the astronaut, or below their feet, or around their waist, it is exactly the same. 2. The wind dancer. In the case with the "wind dancer" :  ( youtube video at https://youtu.be/759p8DHpn5s ) the "Weight Displacement Control" is not applicable. Why? Because the thrust force (i.e. the weight of the "wind dancer") permanently passes through the center of gravity of the "wind dancer" (this is the definition of the center of gravity in physics). With zero offset of the thrust force (i.e. of her weight) from her center of gravity, there is no torque to turn / to re-vector the "wind dancer". But the "wind dancer" is in a high speed air stream (say, 150mph) and her body can interact with the air creating forces and torques that turn and displace her. She has full control over her flight: she can turn at any direction (pitch, yaw, roll) in a fraction of a second, she can also move at any direction (upwards, downwards, to the left, to the right, forwards, backwards). 3. The Portable Flyer With its "true neutral propulsion unit" (neither vibrations, nor reaction torque, nor gyroscopic rigidity; only a force that can "instantly" and effortlessly be vectored towards the desirable direction) the pilot has full control over their flight by combining both:  the "Weight Displacement Control" (of the astronaut) and the "Aerodynamic Control" (of the "wind dancer"). For more, you can read the "DEVICE TECHNICAL REPORT" at https://www.pattakon.com/GoFly/index.html See the "aerobatic maneuvers" of Zapata with his JetPack (several youtube videos). He has only "weight displacement control" (at least at small medium speeds). The Portable Flyer pilot has both, "weight displacement control" and "aerodynamic control" from taking off to landing. And "If the machine gets itself into an unusual attitude, recover" is easy and fast. For more, at the https://www.pattakon.com web site read the topics (menu at left) "OPRE engine", "PatOP engine", "Tilting Valve", "Portable Flyer", "Safer Flying", "GoFly BOEING contest" Thanks Manolis Pattakos Edited on 21-10-2020 07:06 |

| 21-10-2020 07:42 | |

| Xadoman★★★★☆ (1035) |

Thanks Manolis for joining and claryfing your designs. I am pretty sure that your portable flyer is going to work. My intuition says that the flight control should be analogous to the jet pack system. |

| 21-10-2020 12:08 | |

| Into the Night (21582) |

manolis wrote: Nope. The crankshaft is. The cylinder head is very cheap by comparison. manolis wrote: This design does need a complex connecting rod however. That is also not cheap. manolis wrote: Yes, thermal efficiency improves. I've already said this. You still have to remove excess thermal energy from the combustion area, however. manolis wrote: The do not run unloaded. manolis wrote: A bit different. Not much. manolis wrote: I am not talking about small jet packs. I am talking about jet engines, as might be found on a 737. These are VERY efficient at altitude. manolis wrote: It is easy to get. I have seen such aircraft before, in varying designs. The drawings do not show any sort of fuel tank or delivery system. That's going to affect things. manolis wrote: Astronauts don't fly. They float. manolis wrote: There is torque, but it is compensated by the other propeller. Good thing, too. Otherwise the pilot would be spinning and not the prop. 3. The Portable Flyer With its "true neutral propulsion unit" (neither vibrations, nor reaction torque, nor gyroscopic rigidity; only a force that can "instantly" and effortlessly be vectored towards the desirable direction) the pilot has full control over their flight by combining both:  the "Weight Displacement Control" (of the astronaut) and the "Aerodynamic Control" (of the "wind dancer"). For more, you can read the "DEVICE TECHNICAL REPORT" at https://www.pattakon.com/GoFly/index.html See the "aerobatic maneuvers" of Zapata with his JetPack (several youtube videos). He has only "weight displacement control" (at least at small medium speeds). The Portable Flyer pilot has both, "weight displacement control" and "aerodynamic control" from taking off to landing. And "If the machine gets itself into an unusual attitude, recover" is easy and fast. [/quote] Already read the technical report. Some designs can recover. Others can't so easily. manolis wrote: Already read it. My opinions still stand. The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 21-10-2020 12:08 | |

| Into the Night (21582) |

Xadoman wrote: He didn't clarify his design. He just reiterated the same information I used. The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 22-10-2020 07:40 | |

| manolis☆☆☆☆☆ (10) |

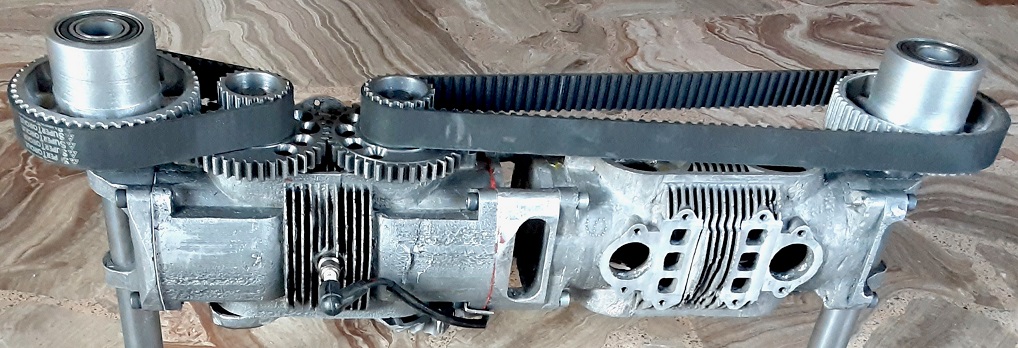

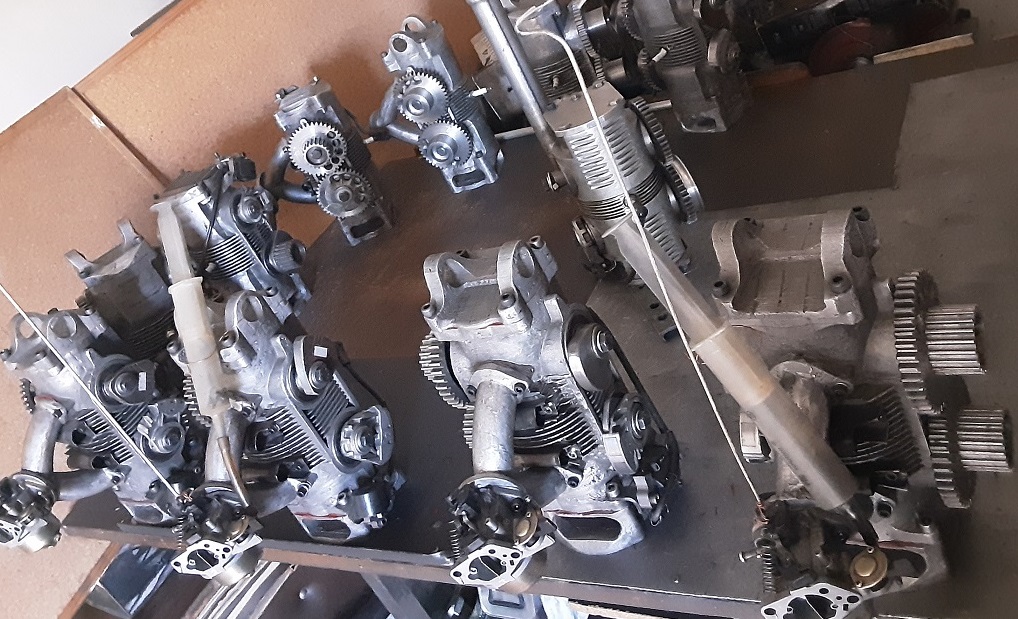

Hello "IntoTheNight" You write: "The crankshaft is. The cylinder head is very cheap by comparison." The machining cost to make a crankshaft is in another order of magnitude than the machining cost to make a complete cylinder head. A classic / expensive car (no spare parts available) that needs a new crankshaft, is a low cost and fast adventure. But if the classic car needs a new cylinder head, identical to the old one, the repair will last several times longer, and will cost several times more. But let's get back to the "expensive crankshafts" of the Opposed Pistons. The AchatesPower three-cylinder Opposed Piston engine (a design similar to Junkers' Jumo engines) has six pistons, has the vibration-free quality of a six-in-line four-stroke engine, it also has three combustions per crankshaft rotation as the four-stroke six-in-line. Did you think that the Achates Opposed Piston utilizes two short crankshafts (each having three crankpins) while the six-in-line needs a long (and so substantially more "flexible") crankshaft with six crankpins? Which is more expensive? The single long crankshaft or the two simple / short crankshafts (made, say, by dividing the long crankshaft in two). But there is more: the four stroke engine needs some 50% more capacity (bigger pistons, longer piston stroke) to make the same power with the two-stroke Opposed Piston. I.e. each of the two short crankshafts of the two-stroke has smaller crankpin offset (piston stroke) and needs thinner crankpin and main journal. The Opposed Pistons are not expensive due to their need for two crankshafts. You also write: "They do not run unloaded." We talk for the synchronizing gearwheels of the OPRE Tilting. Any idea for the order of magnitude of their load relative to their normal load if they were used to transfer the power? If they run with 100 times, or 1,000 times lower loads, then we say that "they run unloaded". You also write: "A bit different. Not much." So, to increase the available time for the combustion by 1/3, and to transfer the thrust loads away from the hot exhaust ports, is a "bit different". I suppose you know more dramatic changes in the combustion process made in the last years. Please let me know some of them. You also write: "I am not talking about small jet packs. I am talking about jet engines, as might be found on a 737. These are VERY efficient at altitude." No they are not. The modern Diesel engines (in trucks) run at 10% higher efficiency than the jet turbines of the big airplanes. Even some small Diesels in cars run at better efficiency. As for the giant 2-stroke marine engines, their overall BTE is over 50%. You also write: "It is easy to get. I have seen such aircraft before, in varying designs. The drawings do not show any sort of fuel tank or delivery system. That's going to affect things." And "No fuel tank. This thing is going to require fuel. A lot of fuel. The pilot is going to have to wear the fuel tank. Further, wearing such a thing is not only heavy, but interferes with the air resistance method of controlling the machine." Why you think it will consume "a lot of fuel"? Consider a motorcycle running at 250Km and the Portable Flyer flying at the same speed. Most of the power is consumed for the aerodynamic resistance. The motorcycle has a few times more frontal are (as compared to the Portable Flyer cruising horizontally). The fuel tank(s) can be located at the back of the pilot (in the lower end of the frame), on at the lower side of pilot's legs, or anywhere else. Here is a youtube viseo with the OPRE Tilting engine running free on the floor. https://www.youtube.com/watch?v=3IRtfc7KayM It is a 350cc two-stroke OPRE Tilting Opposed Piston engine. Its balancing (the balance webs secured at the ends of its two crankshafts) is static (it should be dynamic for complete vibration-free run). Quote from another forum: PORTABLE FLYER PROGRESS In the following photos they are shown the first OPRE Tilting prototype engine (at the center; its casing, pistons, connecting rods and covers are made of billet aluminum "7000") surrounded by ten "all-cast" OPRE Tilting Engines (made of A356-1 aluminum alloy (6.5-7.5% Si, 0.3-0.45% Mg); the material is from used light-alloy car-wheels):  Two of the engines (4th and 5th from right, those with the short top covers), are "broom version" power plants (power output from opposite side of the two crankshafts).  The ten "all cast" engines are for four Portable Flyers and two "Broom" Flyers.  What is missing is: [list]the ignitions from the three engines at right (first photo), the machining (CNC mill) of the sprockets on the hubs of the 8 synchronizing gearwheels (the rest 12 are ready), better carburetors (or, preferably, fuel injection), propellers with their sprockets and toothed belts, and the frames securing the engines to pilot's body. [/list] Here is how the "DEVICE TECHNICAL REPORT" for the GoFly / BOEING contest begins (more at https://www.pattakon.com/GoFly/index.html ) : PORTABLE FLYER ARCHITECTURE AND BASIC DESIGN CHARACTERISTICS The PORTABLE FLYER comprises two OPRE Tilting Engines secured to each other to form (with their casings) the personal flying device's "backbone". The one engine drives two counter-rotating propellers arranged above the backbone, the other engine drives two counter-rotating propellers arranged below the backbone. The following presentation deliberately focuses on the engines because the PORTABLE FLYER is actually its engines . . . The Portable Flyer is actually its engines. Thanks Manolis Pattakos |

| 22-10-2020 10:11 | |

| Xadoman★★★★☆ (1035) |

Manolis, how do you start the engine before take off? |

| 22-10-2020 19:59 | |

| Into the Night (21582) |

manolis wrote: It is not just machining or machining costs. Obviously, you've never built anything larger than these prototype small engines. manolis wrote: Not true. It is not just machining costs. You also are ignoring mass machining and manufacturing techniques. Apparently you have little experience with them. manolis wrote: Argument from randU fallacy. You are making up numbers. A joule is a joule. Yes, the engine is more efficient. I am not disputing this. Why are you continuing this line of spam? manolis wrote: Pistons are cheap. manolis wrote: Semantics fallacy. Argument from randU fallacy (you are making up numbers). manolis wrote: Yes they are. They are the 2nd most efficient engine made. The most efficient is a diesel electric locomotive. Some ship engines approach this as well. manolis wrote: No, they don't. They don't move as much mass for the same fuel as what I've mentioned. You are failing to take into account the effects of friction and drag. Again, I wonder about your experience designing aircraft. You have so far ignored the effects of friction, drag, and stability in flight. manolis wrote: Argument from randU fallacy. manolis wrote: Still require tanks somewhere. I would say at least five gallons for a safe and reasonably long flight. That will weigh about 30 pounds. Then of course, there is the induction system and exhaust system to consider. They also add complexity and weight. The frame should be pretty light at least. manolis wrote: An aircraft is more than just engines. It is obvious to me you've never designed an aircraft before. I like the overall design concept, but it is going to take more than just a few simple sketches and an engine to build it. My concerns remain the same. The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 22-10-2020 20:00 | |

| Into the Night (21582) |

Xadoman wrote: Pull starter? Electric starter? Not yet considered? Battery for glow plugs or spark plugs? That adds weight too. Going to have to find a place to stow that as well. The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 23-10-2020 07:46 | |

| manolis☆☆☆☆☆ (10) |

Hello Xadoman You write: "Manolis, how do you start the engine before take off?" For the moment the engine starts by an electric motor. Here is a video wherein the first prototype is cranked manually. https://www.youtube.com/watch?v=NfbIl_fnsM4 With the propellers on, the engines will be started manually. An electric starter will be an option. Internally the engine runs like:    Youtube video (assembly / disassembly) at: https://www.youtube.com/watch?v=dmSPrhe4XU4 Hello IntoThe Night. The spark ignition OPRE Tilting engines you see running, need not batteries for their ignition (magnet on a balance web, coil etc). I admit that I never built an airplane. Have you ever built one, or a turbine for a BOEING 737? It is meaningless to continue the debate. The readers can judge who knows what. Thanks Manolis Pattakos Edited on 23-10-2020 08:21 |

| 23-10-2020 18:22 | |

| Xadoman★★★★☆ (1035) |

It is going to revolutionalize aviation if this kind of flyer is going to be on sale with an affordable price. My concern is safety with flying. I do not like flying with planes because I know that if something goes wrong with the plane then you can do nothing to save yourself. With the portable flyer I would also be concerned with propellers that are in close proximity with the head. I would be more calm if there would be some kind of safety screen between the head and the propellers. Also, for lubricating the almost non loaded synhronizing gearswheels I recommend a product calle XADO. This creates a ceramic coating on the gearswheels and the friction is greatly reduced. Here is a good comparison video about how XADO works with bearings and even restores previous damage. https://www.youtube.com/watch?v=E6ZN-Zes88c&ab_channel=XADOChemicalGroup |

| 23-10-2020 19:12 | |

| James___★★★★★ (5513) |

Xadoman wrote: That's pretty cool. Do you know if it will work for babbet bearings? It might help to put off rebushing a bearing for a while. Edited on 23-10-2020 20:09 |

| 23-10-2020 21:43 | |

| Into the Night (21582) |

manolis wrote: The ole' spin the prop, eh? . That's the nice thing about starters. You can use a pull start, electric start, or just flip the propeller by hand (difficult with this design!). A pull start will be yanking the thing down on your head. An electric start is heavier, but seems the more viable option. manolis wrote: So you are thinking of using a magneto? Simple, but that kind of takes away the advantages of diesel, doesn't it? Glow plugs for a diesel will need power for them before the engine starts. It can be recharged by a small alternator or generator, but again, that's weight. Perhaps just using a magneto would be the better choice, but that presupposes a gasoline engine. manolis wrote: Thought so. A lot of important things haven't been considered yet. manolis wrote: Yes. I have built three aircraft (or actually have built two and I am working on a third). I also help others on the field with their projects, and I am also a licensed aviation mechanic. We usually just stick some handy small engine on them. The one I'm building will use a Subaru boxer engine (I am converting the FADEC system now). I will put out about 180hp. I have also of course built numerous model aircraft (which are real aircraft). You might try to build a model of your design to see how it behaves. It might enlighten you to some practical needs for your aircraft. manolis wrote: Despite the name of this site, there are no debates here. Only conversations. If you want to run away, that's your choice. The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 23-10-2020 22:04 | |

| Into the Night (21582) |

Xadoman wrote: The old dream. No, personal flyers of various designs are already available. This is just another one. It does, however, have some unique characteristics about it that I like. Xadoman wrote: A good concern. It is the same with me. Before I put my precious pink tussie into the air with an aircraft I built, I do a thorough ground handling test on it, and test control responses before it ever leaves the ground. I check every aircraft before I fly it. Xadoman wrote: You can be a pilot and drive the thing yourself, if you want to go through the training. Depending on a pilot (and copilot) does put your trust in these two men, but the machine they are driving is built amazingly well (shamless plug for Boeing?). If an engine fails in flight, it's a glider. Just treat it like one. No need to panic. Even 737s will glide reasonably well. The wings on these things are built tough. It's really hard to break a wing. Some time you should see the wing test jig they've made at Boeing. That thing can bend a wing until the tips almost touch, but it does not break! No one is allowed anywhere near the area when a wing is tested, of course! Jet engines are very reliable. Even if a bird flies into one, it generally just keeps right on going. 737s have two. It can fly and even climb on one of them. It's no problem for the pilot to find a suitable field and put down. Boeing recently had problems with it's 737MAX design. These are being corrected. Before this plane enters service, it will be a safe aircraft to fly. The only reason two of them crashed (in foreign countries flown by foreign pilots) is poor training in those countries. U.S. pilots recognized the problem and took proper steps. The trim system is not considered a critical flight control. It can be dealt with when it goes wacky. Xadoman wrote: Not a problem. Just don't stick your hand, head, or anything else up there. Treat it like a lawnmower. Respect those blades. Xadoman wrote: Not needed, and would actually only add weight and a place for debris to get caught in before it rains down your head at high speed. No screen is a better way to go. No place for debris (that gathers when the machine is not in use) to gather. Don't stick hands, feet, head, or anything else in the blades. It looks like this design is not even in arm's length of reach of the blades. Xadoman wrote: Nothing can restore previous damage. If a gear is compromised, it must be replaced. The last thing you want is a broken tooth jamming the mechanism. All gears need lubrication. Sometimes, in extremely light loads for small gears, the material they are made of provides sufficient lubrication, and the gears can run 'dry'. Examples of these are nylon gears in small devices. Sometimes a coating of light machine oil is sufficient. This machine uses power gears on a pulsating load. This is very hard on gears. They need to be built extra tough for this purpose and continually lubricated (putting them in an oil bottle is sufficient). The gearbox need not be large, but it must be filled with oil and the gears specially made for this kind of load (not cheap). Gearboxes of this sort are already found on aircraft for their propellers. Perhaps retasking one of these would work for the prototype? The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 23-10-2020 22:08 | |

| Into the Night (21582) |

James___ wrote:Xadoman wrote: Babbet is already a kind of lubricant. Slip bearings of this sort are designed to use sacrificial material (the babbet) as the wear surface to protect the crankshaft (the expensive part). Replacing the bearings is a normal part of the maintenance of these engines. You don't rebush them. You replace them. They are not particularly expensive. Getting to them is the labor expensive part. The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan Edited on 23-10-2020 22:08 |

| 23-10-2020 23:54 | |

| Xadoman★★★★☆ (1035) |

Nothing can restore previous damage. Of course it would not restore major damage like broken tooth. But overall wear and tear could be cured in many cases. Increase in compression and an ability to keep going quite a long time without oil are some of its benefits. Take a look at this demonstration for example: https://www.youtube.com/watch?v=BFvTUwVjqLw&t=31s&ab_channel=XADOPhilippinesOfficial Most of the engine wear is right after the start up when oil has not reached to the critical places. That is why turbo shafts and crankshafts get destroyed. Using a similar product could prevent such nasty suprises. Edited on 24-10-2020 00:00 |

| 24-10-2020 11:50 | |

| manolis☆☆☆☆☆ (10) |

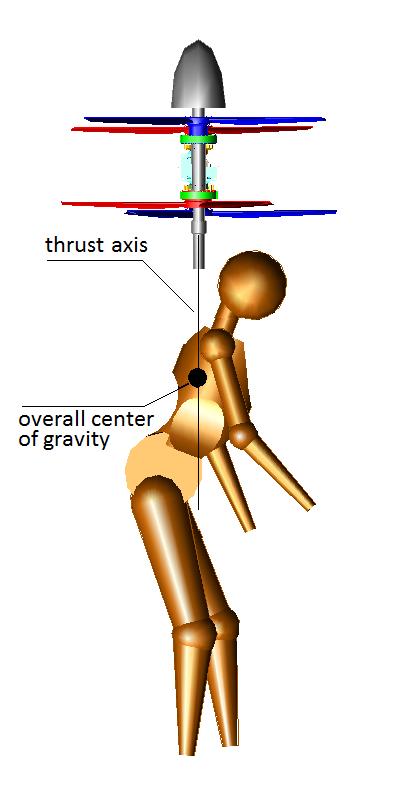

Hello all. Here are the specifications of the JB10 and JB11 JetPacks of Mayman:  Spot on the dry weights. Adding, say, 30 liters (24Kg) of kerosene / Diesel fuel (otherwise the flight duration will be shorter than 10 minutes), the total weight of the device at take-off becomes 59Kg (130lb) and 76Kg (167lb). The JB11 has six turbines for safety (if one turbine fails, the functional ones allow it to fly and land safely). But this version (JB11) is too heavy. Only few people can carry such a weight on their back / legs without problem. The JB10 is less heavy, but it cannot fly or land if the one turbine fails (the JetPack is no longer controllable: it will start spinning fast: with the center of gravity more than 0.2m away from the thrust axis (i.e. from the shaft of the functional turbine), it will make its first side loop (?) in 1.5 second, its second "side loop" will last substantially less than 1 second and so on. No case of safe landing or control. In this photo / drawing:  Mayman (at right) wears his JB10 JetPack. Compare the distance and location of the shafts of the two turbines with the distance and location of the rotation axes of the four propellers of the Portable Flyer (at left). A difference between the two arrangements is the higher position of the Portable Flyer propulsion unit (higher center of gravity). However at flight what does matter is the location of the overall thrust axis; and the thrust axis is, more or less, at the same position and passes near the center of gravity in both cases. I.e. the big difference will be on the ground with the one unit being substantially more lightweight but arranged higher. In both cases the "upper torso / back" of the pilot is secured to the propulsion unit. The turbines and the torso / back of the Mayman comprise a fixed body. The propulsion unit and the torso / back of Portable Flyer's pilot comprise a fixed body. Using their free body-parts the pilots instinctively control their flight in both cases. As Mayman says, the average person needs three hours of tethered training before free low-height flights over water. Mayman cannot use, at small / medium speeds, aerodynamic control because the air speed on his limbs / head is small (and he has to keep his limbs away from the supersonic hot exhaust gas), so he needs additional mechanisms for the yaw control. The Portable Flyer pilot has aerodynamic control from take off to landing for the yaw (and much more). Another difference is the safety offered by the Portable Flyer: in case the one propulsion unit fails, the other with its two propellers continues to run independently, allowing both: controllable flight and safe landing. There is no pitch control in either case. The automatic pitch provided by the PatPitch propellers:  allows higher final speed and lower engine loads; more at https://www.pattakon.com/pattakonPitch.htm Thanks Manolis Pattakos |

| 24-10-2020 22:04 | |

| Into the Night (21582) |

Xadoman wrote:Nothing can restore previous damage. Nope. Once damaged, it's damaged. No magick liquid can fix the damage. Xadoman wrote: Spamming of products is generally discouraged on this board. It is not an ad opportunity. Xadoman wrote: Not true. The oil in bearings is already there. An engine is preoiled during assembly for just this reason. Xadoman wrote: They don't. The bearings take it instead. You ARE using bearings, right?? The only reason a crankshaft or turboshaft is going to get damaged is from lack of oil pressure, overstressing the engine, or not maintaining the bearings. Xadoman wrote: No nasty surprises if you maintain your machine. Engines have a 'life span'. That span is determined by the time interval between required bearing shell changes, ring changes, gasket changes, etc. These are replaceable parts in the engine. They must be replaced from time to time as part of normal maintenance. Gaskets today are incredible. Instead of lasting a mere year like they used to, head gaskets can now last almost the life of the car. The car gets crunched in a salvage yard with perfectly good head gaskets in them! Due to smaller throw and better materials, bearing shells have improved a lot for cars. For larger throw engines like aircraft engines, bearing shells still need to be changed after a few thousand hours. It's improving though. Jet engines spin rapidly in a very hot environment. Those bearing shells also need to be replaced regularly. It's brutal in there. Hitting a prop, even to just make a divot in the dirt, is enough to require an engine teardown to make sure nothing got bent up. There have been times when I found the crankshaft bent like a pretzel after one of these. When it's that bad, the case and the crankshaft are usually garbage. The crankshaft is for sure. Usually several cylinders got damaged as well in a bad prop strike like this (the last one I saw was when the plane landed gear up). The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 25-10-2020 03:45 | |

| duncan61★★★★★ (2021) |

ITN wrote Nope. Once damaged, it's damaged. No magick liquid can fix the damage. I have always had second hand cars and the first thing I do is drain the oil and change the filter then new oil not synthetic and put an oil treatment from Pro-ma or liqui moly in and over the next 50 Km or so you can feel the engine spinning better and the idle will go up a little and cold starting is easier.Some mechanics will tell you its a gimic but it has always worked for me.Theres the magick liquid.The copper in the solution fills in all the microscopic pits in the metal moving parts.It helped that my best friend was a Pro-Ma agent but he has passed on so now I use the Liqui Moly product and it works.I do the fuel treatment as well |

| 25-10-2020 05:59 | |

| manolis☆☆☆☆☆ (10) |

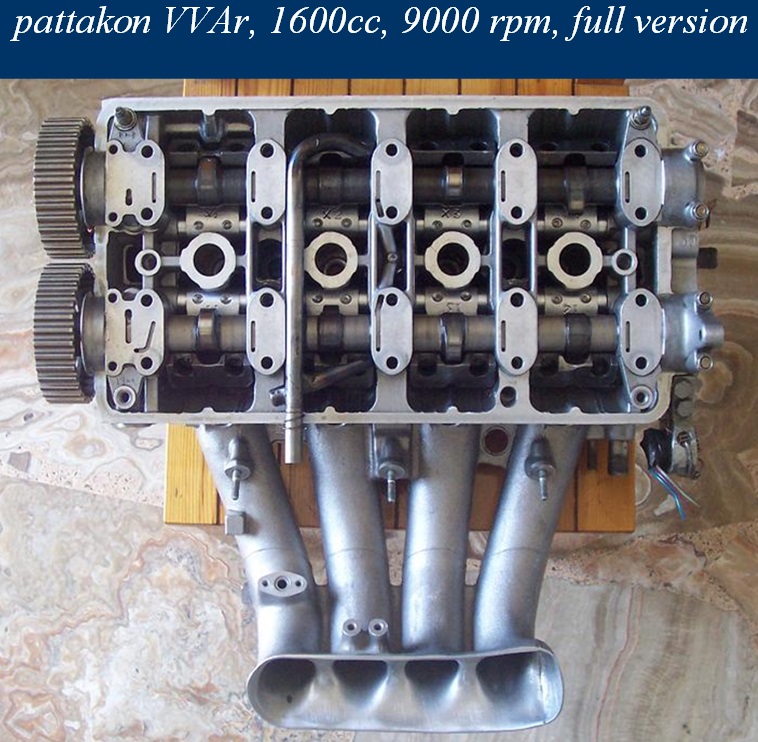

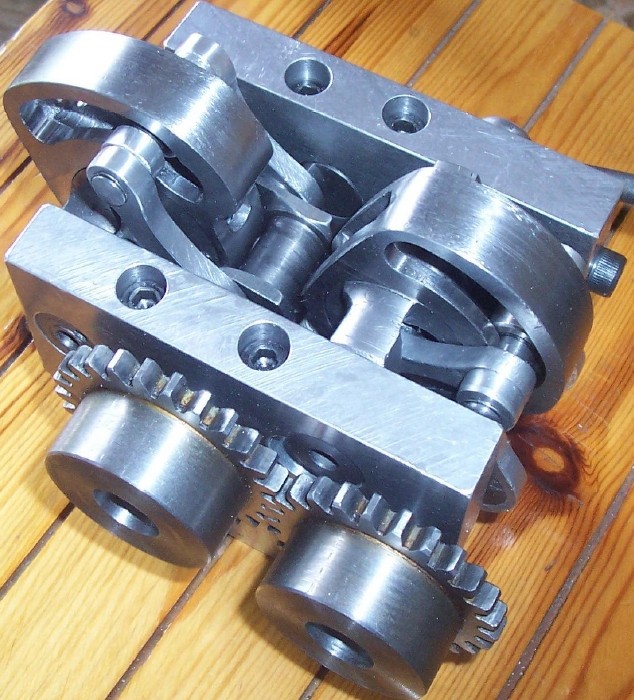

Hello all. Cylinder Head work Here is the cylinder head cover of a Honda B16A2 VTEC 1,600cc, 16v engine modified to pattakon VVA-roller:  Here the cylinder head cover is removed (this is the light version: only in tha intake valves):  Here is the cylinder head from below:  Here is the zero-cost ITB (independent throttle body) of the engine (no throttle valves, at all; the intake valves do the throttling):  Here is shown the mechanism of the VVA-roller and how it works (the sliding friction of the original engine has replaced by ronrolling friction; as Honda says, the rolling friction of their S2000 saves 75% of the friction in the cylinder head):  The control shafts are directly connected to the gas pedal by the gas cable. The deeper the gas pedal is pressed, the more the control shafts rotate increasing the valve stroke. When the gas pedal is released the normal valve springs restore the control shafts to their "idling" position. Depending on the control shafts angular position the valve lift profile varies continuously from zero (for valve deactivation if desirable), to tiny (for idling), to mild, to medium, to racing (top curve), all in the same engine, all instantly available:  The Low rpm (green) Valve Lift profile is different for the two intake valves of the same cylinder of the original VTEC engine (similarly for the two exhaust valves of the cylinder). The red and green curves are the only available valve lift profiles in the original Honda VTEC engine. The blue curves are only few - of the infinite available - valve lift profiles the "pattakon VVA roller version" provides. The quick moving parts are lightweight: the original Honda rocker arm assembly weighs 0.26 Kp while the complete rocker arm of the Pattakon VVA (the two rollers included) is less than 0.15 Kp. Even with the toughest valve springs, the engine at normal conditions (i.e. low to medium revs) "feels" (as regards friction, wear etc) by far softer springs. Here is the full version (VVA-roller on all valves, intake and exhaust) with the ITB on:  Here are two cars:  The white one has the pattakon-VVA-rod on its cylinder head, the black one (Honda 1600cc 16v VTEC) has the pattakon-VVA-roller Full version Variable Valve Actuation system in its cylinder head. In this youtube video the above black car is accelerating on a public road: https://www.youtube.com/watch?v=-zzW8YkReLU *** how a youtube video is inserted in this forum? *** More at: https://www.pattakon.com/pattakonRoller.htm https://www.pattakon.com/pattakonRollerLight.htm https://www.pattakon.com/pattakonIdleValve.htm This PowerPoint: https://www.pattakon.com/DVA_files/pattakonVVAs.pps is the presentation of the pattakon VVA's in the International Engine Expo 2008, Stuttgart Germany. Have a good reading. Thanks Manolis Pattakos |

| 25-10-2020 09:41 | |

| Xadoman★★★★☆ (1035) |

duncan61 wrote: Same with me. The only difference is that I do not drain the old oil because as recommended the effect of such products is bigger with an old oil. With old oil the friction is bigger in critical parts and the product has an easy time finding a way to such places and starts to do its job. The old oil also contains small particles of metal from wear and tear and those particles are also being used to "clue" back to detail to reduce the wear and tear. I once read a 4x4 land rover forum and they had a lot of problems with broken cranckshafts with 2,7 and 3.0 hdi engines( PSA french engine). The crankshaft just gets broken out of the blue no matter how good you have been with the maintanance. They all admitted after studying the issue further that the crankshaft of the engine is underdimensioned for a big car like that but that alone should not cause such failures. Many engines did not blow up. One guy , a mechanic who saw a lot of failures, found out that the biggest killer for those engines is a cold start up after long time staying. Therefore he recommended an oil treatment with some kind of product ( do not remember the name) but he sweared that after the treatment with such product the engines did not suffer those kind of failures anymore. I myself treat every second hand car I buy with this kind of product for prophylactic reasons. I like the idea that even after broken sump from hitting the rock or something I could go on and limp home. I also treat gearbox and fuels system. Edited on 25-10-2020 10:24 |

| 25-10-2020 10:10 | |

| Xadoman★★★★☆ (1035) |

Manolis, this is just beautiful stuff you can do with these engines. Most of the time in automotive forums I see guys porting the heads and bolting on bigger and bigger turbos but all of those cars become terrible to drive and unefficient in normal conditions. I am amazed that most of those " state of the art" BMW ,Honda etc etc vvt solutions are pretty shitty designes compared to your inventions. It also shows how much work and money goes into the head desing if you want to make right. Just wanted to ask - is there any point modifying a diesel engine head like you did with the citroen and honda. I myself am a little bit of diesel engine fan because I like the torque and efficiency of the modern turbodiesel engine. I have a 2.0 hdi berlingo just for the reference. |

| 25-10-2020 19:21 | |

| Into the Night (21582) |

duncan61 wrote: The stuff is not a gimmick. There are variety of solutions like this that tend to seal pores in the metal of an engine, allowing it to run a bit easier. It still will not fix a damaged or worn gear, or replace the babbet in slip bearings or the need for oil in the engine. The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 25-10-2020 19:50 | |

| Into the Night (21582) |

Xadoman wrote:duncan61 wrote: Nope. Engine oil collects acids and carbon particulates in it. That will eventually plug engine oil galleries, and the acids don't do your engine any good. Xadoman wrote: Nope. Hydraulic pressure is equal throughout the system minus friction from oil galleries (and the hydraulic friction of the bearing surfaces themselves, of course). Crappy oil doesn't help the additive, and can damage your engine. Xadoman wrote: If your engine is making metal in the oil, you have bigger problems than any additive can fix. Your engine is self destructing. Xadoman wrote: Some people make crappy crankshafts (and engines). Xadoman wrote: I don't believe this story. A crappy design in a crankshaft is a crappy design in a crankshaft. Cold startup makes no difference. Xadoman wrote: Nope. An engine will not run without lubrication. Oil is more than just a lubricant. It also gets rid of excess thermal energy from the engine. Don't run the engine without oil. Xadoman wrote: Knock yourself out. Fuel systems do not need treatment. They are engineered to run just fine as they are. The only moving parts are the metering system (typically a fuel injector these days, essentially a high pressure squirt gun), a fuel pump (usually a vane, but sometimes a reciprocating pump), a regulator valve, and possibly a gas level measuring lever (some systems use a capacitance meter). None of these devices benefit from treatment of any metal sealant. Gearboxes do not benefit from the treatment either. While gears do have friction from their bearings and tooth engagement, oil is your best bet here. Sealing the pores of these materials does essentially nothing. A fuel system CAN benefit from a good cleaning, which some liquids can do. If it's already clean, no difference. Be sure the liquid you use is compatible with the fuel used in the machine (which will also make it compatible with the gaskets used in the fuel system). The Parrot Killer Debunked in my sig. - tmiddles Google keeps track of paranoid talk and i'm not on their list. I've been evaluated and certified. - keepit nuclear powered ships do not require nuclear fuel. - Swan While it is true that fossils do not burn it is also true that fossil fuels burn very well - Swan |

| 26-10-2020 00:26 | |

| James___★★★★★ (5513) |

manolis wrote: Do you think an electronic solenoid could allow for controlling your lifter invention? Then you might be able to change the throttle response if you want. I like your jet pack design. Is there any certain motor that you based yours on? |

| 26-10-2020 07:51 | |

| duncan61★★★★★ (2021) |

So the plenum is under constant boost and the valve movement controls the charge entering the cylinder.The valves are opened and closed mechanicaly meaning no valve bounce.Depending on engine size there is no max RPM.I honestly thought after fuel injection engine management and variable valve timing it was all done.I was wrong |

| 26-10-2020 12:46 | |

| manolis☆☆☆☆☆ (10) |

Hello Xadoman A Diesel engine can't operate at high revs (at 4,000 - 4,500rpm the power output drops steeply due to the inefficient combustion of the fuel: it needs more time; this is what the pulling-rod OPRE and PatOP and PatPortLess engines offer: more time for efficient combustion of the Diesel fuel). With the rev limit at 4,000 - 4,500 rpm, a VVA is meaningless. Hello Duncan61 Yes, the intake valves do, among others, the job of the throttle valve. In city traffic the "throttless" Honda VVA-roller needs not more than 2.0 - 2.5 mm intake valve lift to follow the traffic. In the highway the same car can run with 12mm intake valve lift, say as a racing car, with the rev limiter set at 9,000rpm not for the sake of the valve train, but to protect the underneath engine. However the most advanced pattakon VVA is the DVVA (desmodromic VVA, more at https://www.pattakon.com/pattakonDesmo.htm ) It needs not valve springs and it is more variable than the VVA's in the white and black cars (actually it is a combination of them).  The DVVA was never installed in a car. Despite its problems / limitations, the VTEC system is what made the Honda great (in the Formula1 and in sport / sport-family cars). The VTEC is a two step VVA, with a torque "hole" at the transission point at ~5,000rpm). A good cylinder head has a lot of work, but it can make a big difference. Thanks Manolis Pattakos |

| 26-10-2020 16:10 | |

| James___★★★★★ (5513) |

manolis wrote: I'm not sure if you're aware of this but there is something that might improve the combustibility of diesel fuel. |

| 26-10-2020 18:21 | |

| manolis☆☆☆☆☆ (10) |

Hello James. A Diesel engine is an engine running on the compression-ignition cycle, not an engine burning Diesel fuel. The "compression ignition" cycle (or Diesel cycle) has its own limitations. The combustion has limited time to complete. At higher revs a significant portion of the fuel burns at low "expansion ratios", significantly lowering the Brake Thermal Efficiency (BTE). As far as I know, there is no "true Diesel engine" (the fuel is injected into the cylinder at the end of the compression of the air) that runs efficienlty at high revs. Thanks Manolis Pattakos |

| 27-10-2020 00:34 | |

| James___★★★★★ (5513) |

manolis wrote: And the diesel engine was named after it's inventor. Coke or coal dust was originally used. Somehow the guy didn't think exhausting soot or ash would be a problem. Still, can't discuss an invention without a notarized NDA and proof of identity. I should be home in about 3 weeks. Had surgery and am on meds. As for discussing the idea publicly, just won't happen. That's how ideas get stolen. |

| 27-10-2020 05:12 | |

| manolis☆☆☆☆☆ (10) |

Hello James. You write: "As for discussing the idea publicly, just won't happen. That's how ideas get stolen" Then, do not discuss about your idea. Thanks Manolis Pattakos |

| 27-10-2020 13:27 | |

| duncan61★★★★★ (2021) |

I will share this I had a Ducati in the Army 900 Darmah and it had desmodronic valve. |

| 30-10-2020 13:46 | |

| James___★★★★★ (5513) |

manolis wrote: Magnolia, these guys know that I am pursuing an experiment in atmospheric chemistry and physics. It would show how other atmospheric gasses support the Chapman Cycle. Basically, how is more oxygen added to that cycle? I think if I am successful with that, then I'll be finding opportunities where others missed them. And with the focus on CO2 and other gasses produced by combustion, it might catch some people's attention. @Duncan, when I was in the National Guard, I worked in the motor pool. We had a little bit of everything. |

| 30-10-2020 17:29 | |

| manolis☆☆☆☆☆ (10) |

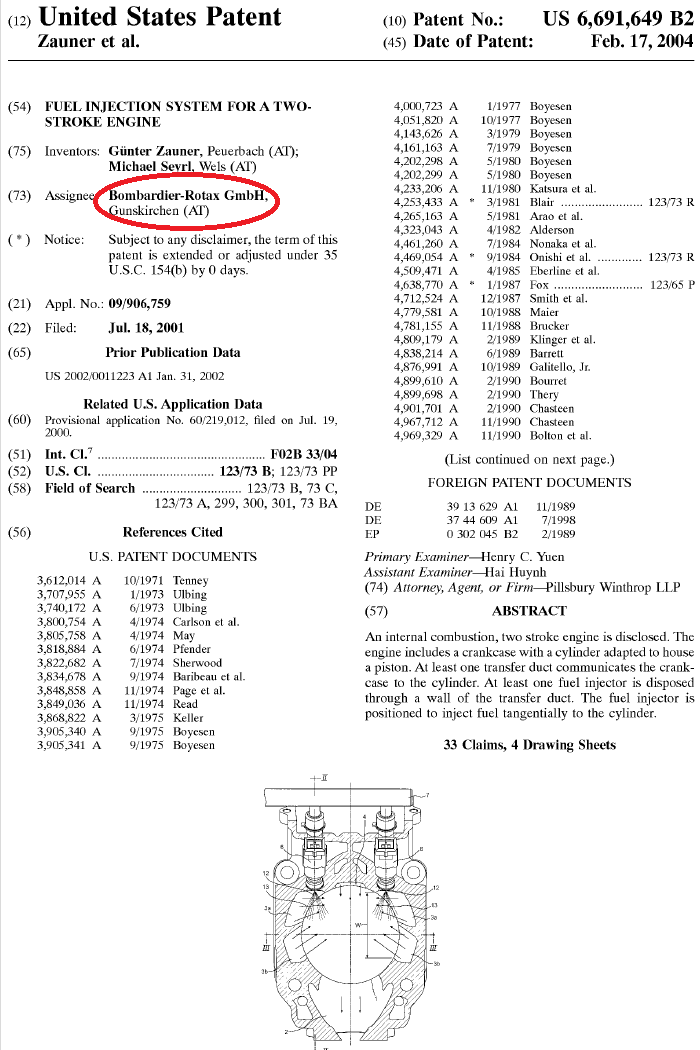

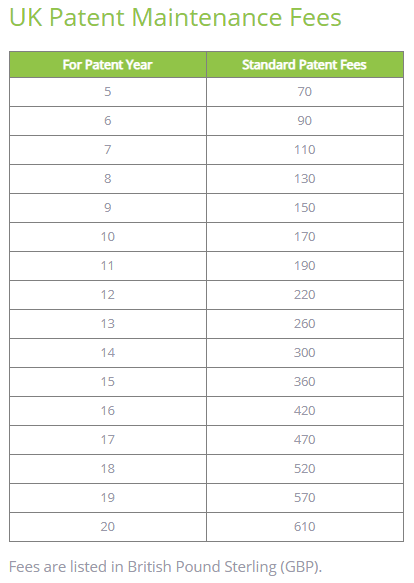

Hello all. Hello James. Some forum members (young engineers and mechanics, thinkers and tinkers) might find this information useful. PATENTING Patenting an idea is, today, the only way to protect your intellectual property. Patenting an idea / invention is not easy. When a Patent Examiner (typically an engineer specialized in a narrow technological area, say in the fuel injection) performs a Search for a Patent Application, the Examiner tries to find documents to "kill" the claims of the patent application. It is his job, his duty. The Set of Claims is the core of a patent application and defines what the applicant considers as his own "intellectual property". If the claims are too "wide", it is too easy for the examiner to "kill" them. If the claims are too "narrow", the patent – if and when granted – will be worthless because it cannot really exclude others from making, using or selling the invention. It is difficult for the applicant to decide for the claims, i.e. for the protection he will ask. Too wide protection? Problem. Too narrow protection? Problem again. Having the Search Report, Parenthesis: The final Search Report needs more than 18 months to complete; Why? A patent application in another patent office is not "open" / accessible / available to the Patent Examiner until it is published, and this happens no latter than 18 months after the initial filling of the application. That is, there is an 18-months time-window during which the applicant and the examiner cannot be really sure what the "Prior Art" is.[/list] End of parenthesis and provided the patent examiner does know to do his work, the applicant can judge whether his invention is really new and really his. Without a Search Report, anybody can claim the ownership of any idea. Only with the final Search Report the applicant can be sure the idea is his own (and this, provided the Patent Office did properly their work, which is not always the case). Yes, there are millions useless patents and patent applications, say like those for "perpetual motion devices" (some patent offices refuse to examine such patent applications), however, there are thousands of good / useful patents. The fight between Apple and Samsung some years ago, was based on their patents. The drug companies make billions based on their patents. Patenting is a useful tool of the modern world. The money you pay is in order an authorized, experienced and highly specialized "third party" to examine your invention and decide if it is new or old. Albert Einstein started his carrier as a patent examiner. The same US patent-office examiner who searches today a Toyota's patent for a new VVA (Variable Valve Actuation system), the same examiner may search tomorrow the patent application for a VVA of a foreign independent inventor (poor or reach, does not matter). And the rules used for the Search and Examination are exactly the same, in both cases. The patenting system has many problems. It should (and it can) be way better. However the patenting system is what we have today in order to see if an idea / solution / invention is ours or not, and in order to protect our Intellectual Property excluding others from "making, using or selling" it. ***************** For instance, here is the cover page of a US patent of Rotax, filed 20 years ago (i.e. it is already expired, i.e. anybody can make, use or sell it):  and here https://www.pattakon.com/tempman/Rotax_Port_Injection_US_Patent.pdf is the complete patent document. The documents related with Rotax's invention were so many, than the "Reference Cited" continues in another page. The patent application was filed in 2001, the patent was granted to Bombardier / Rotax in 2004. Only after the examination of their patent application and the issue of the patent [list]which means, an official / authorized third party, the US-PTO, searched and examined the invention and decided that ir complies with all rules and can take a patent[/list], only then Rotax could claim the specific TPi was their own "Intellectual Property" and nobody else could "make, use or sell" it. *************** PATENTING COST The following costs are for the case the applicant does everything (no patent agent, no patent attorney). US patenting cost For a "small entity" (note: for companies the costs double) an electronically filed "utility" US patent application (having till 3 independent claims and till 20 claims in total) costs as follows: Filing: 1. Basic fee: 160$ 2. Search Fee: 350$ 3. Examination Fee: 400$ Total: 910$ with the filing. After nearly three years, and provided the applicant responded correctly to all requirement of the Examiner / Office (amendments of claims, corrections of disclosure, replacement of drawings etc, etc), a Patent is granted and an Issue fee of 600$ has to be paid. So far you have paid 910+600 = 1510$, and you have a US patent in force for the next 3.5 years. US Maintenance Fees: 3.5 years after the issue of the US patent, a 1,000$ maintenance fee is to be paid (otherwise the patent expires). 7.5 years after the issue of the US patent, another 1,880 maintenance fee is to be paid (otherwise the patent expires). 11.5 years after the issue of the patent, another 3,850 maintenance fee is to be paid (otherwise the patent expires). Provided you paid all the above fees and maintenance fees (1,510 + 1,000 + 1,880 + 3,850 = 8,250$ in total), the patent automatically expires 20 years after the filing of the patent application. UK patenting cost An electronically filed UK patent application has a cost of 310 UK pounds, from filing to grant. The maintenance fees are paid each year (starting the fourth year after the filing) and increase as the years pass through:  For the last year you have to pay about two US dollars per day(!) to keep your patent in force in the United Kingdom . . . There is no World Patent. What there is, is the PCT (Patent Cooperation Treaty) patent application (it cost nearly 3,000$ with the Search and Examination), which gives you the right to file - into 30 months from the first priority - National Applications in each patent office around the world (like the above US and UK patent applications) claiming priority the original patent application. Without a PCT application (and cost), there is a 12 months time limit for filing National Applications in other patent offices claiming the priority of the initial application in a patent office. I.e. what the PCT really offers (besides their Search and Examination) is an 18 months extention of the time for entering into the National Phase in various countries. If something is confusing, please let me know to further explain. Thanks Manolis Pattakos Edited on 30-10-2020 17:56 |

| 31-10-2020 00:32 | |

| James___★★★★★ (5513) |

So you're not interested. I'm okay with that. |

| 31-10-2020 03:32 | |

| HarveyH55 (5196) |

Patents mostly just make lawyers rich... They are basically useless, if you can't afford to defend in court. China doesn't really steal a lot of intellectual property, it's usually handed to them by American companies. And, of course, the courts can only give you a ruling, you still have to collect any damages on your own. Generally hiring another lawyer, and more courts, to compel compensation, if the company still exists at that point... Patents do make sense in some cases, but most of the time, the market window is kind of narrow, and the product becomes useless or obsolete. |

Join the debate Surplus electricity from wind power:

Related content

| Threads | Replies | Last post |

| The USA electricity system - Hourly billing.? | 108 | 02-02-2024 20:52 |

| Using Wind Turbines is Mass Murder | 3 | 01-02-2024 03:00 |

| Offshore wind projects face economic storm. Cancellations jeopardize Biden clean energy goals | 7 | 05-11-2023 20:41 |

| THE FUTURE OF HYDROGEN POWER | 31 | 09-08-2023 19:29 |

| Electricity | 19 | 07-08-2023 19:11 |